Piping Leak

1. Emergency Isolation Valves (EIVs)

The Emergency Isolation Valves cannot be installed in the lines leading to all equipment that may leak. However, they are installed in the lines leading to equipment that, (experience shows) is particularly liable to leak (for e.g. Very hot or cold drain lines or in lines from which, if a leak did occur earlier).

In all these cases, once the leak starts, particularly if it ignites, it is usually impossible to approach the normal hand-isolation valves to close them. Emergency Isolation Valves can be operated electrically, pneumatically, or in some cases hydraulically. The following incident show how useful they can be.

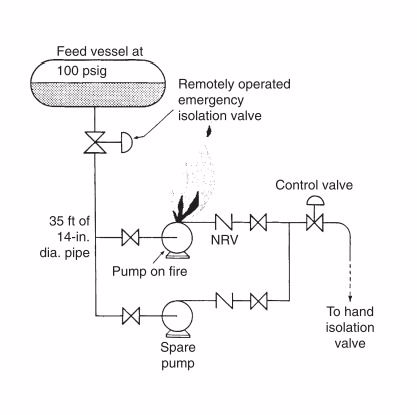

- A leak of light oil from a pump caught fire. The flames were 10 m (33 ft) high. From the control room, the operator closed a remotely operated valve in the pump suction line.

- The flames soon died down, and the fire burned itself out in 20 minutes. It would have been impossible to close a hand-operated valve in the same position. And if the emergency valve had not been provided, the fire would have burned for many hours. The emergency valve had been tested regularly. It could not be fully closed during testing but was closed part way. Back-flow from the delivery side of the pump was prevented by a check (non-return) valve. In addition, a control valve and a hand valve well away from the fire were closed (Refer below figure).

2. Injecting a sealing fluid into a leaking flange using a proprietary process such as Furmaniting. (Bolts are not to be over stressed).

3. Confining the spread of leak by water spray or steam curtains.

4. Controlling the evaporation from liquid pools by covering with foam. (Can be used for Chlorine and Ammonia spillages as well as hydrocarbon spillages if suitable foams are used).

5.Adding a less volatile liquid to a spillage to reduce its volatility. When some liquefied petroleum gas (LPG) got into the drains, some gas oil was poured down them to absorb the LPG and reduce the chance of an explosion.